Injection Molded Plastics, Are Objects Or Forms Made Of Plastic That Have Been Created By The Process called Molding

|

| Injection Molded Plastics |

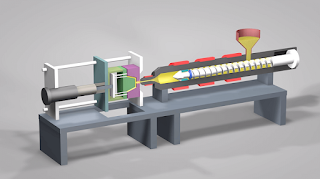

Manufacturers fill a mould chamber that is formed like the intended product with molten plastic resin during the plastic injection moulding process. A variety of frequently used products, including ordinary plastic objects like bottle tops as well as remote-controlled casings, syringes, and more, are made using the injection moulding process. Moreover, it is frequently utilised in the production of larger objects like automotive body panels. Plastic injection moulded components are used in a lot of machinery and car parts.

These components include truck stairs, inside

door panels, cup holders, radio controls, and vehicle and truck bumpers.

Injection Molded Plastics components are prized for their

robustness, resistance to corrosion, and resistance to ultraviolet rays. Injection

moulding operates on a fairly basic concept. The solid polymer is transformed

into a molten fluid with a sufficiently low viscosity when the plastic

substance is heated past its melting point. After that, it is pressed into a

closed mould that establishes the shape of the finished product. The cycle

consists of four stages. The clamping, injection, chilling, and ejection stages

are these steps. Moulds for plastic injection can withstand up to one million

cycles. The lifespan of Injection Molded Plastics is influenced by the climate, upkeep,

structure, SPI categorization, and other elements.

Due to the fact that only the

precise amount of plastic required for a product is injected into a mould,

injection moulding is a naturally low-waste technique. We may reduce waste by

recycling whenever possible, scheduling manufacturing runs to optimum

efficiency and practising energy conservation by taking a strategic

perspective on product design and production processes. Bottles, plastic bags,

and wraps, as well as park slides, are all made with low-density polyethene

using the injection moulding process. The resistance to chemicals and moisture

of this material is advantageous. The base, the hopper, the barrel, and the

clamping unit are the four basic parts of an injection moulding machine. The

split mould, clamping unit, injection unit, and hydraulic unit are examples of

smaller parts. There are other smaller parts like the nozzle and ejector pins.

Comments

Post a Comment